How to manage 2021’s ongoing capacity crunch

Ever since coronavirus disrupted the supply chain, shipping capacity has been tight. Even though government-mandated quarantines are ending and businesses are opening up, the capacity crunch continues to impact business operations across the country.

The causes of the current capacity crunch

Both manufacturers and retailers are trying to bounce back from COVID-19 and quarantine. As consumers return to brick-and-mortar retail, businesses are trying to restock as quickly as possible.

But a revved-up economy is running straight into a wall of capacity issues. Three of the most pressing problems are:

1. The system is still recovering from the impact of COVID

Quarantine caused a huge change in consumer spending. Dollars that were going to travel and restaurants suddenly shifted to home entertainment and home improvement. US ports are jam-packed and Asian ports are still waiting for their containers to be returned. Until that changes, shipping between Asia and the US will be much slower than usual.

2. The driver shortage is only getting worse

Although the driver shortage has been a problem for years, the pandemic worsened the problem. Businesses have responded by raising driver pay, but so far it hasn’t been enough. There simply aren’t enough drivers to ship everything that’s sitting in American warehouses.

3. Truck production has slowed

Semiconductor manufacturing, which impacts the construction of everything from trucks to laptops, slowed down when coronavirus closed factories across the world. As factories opened back up a surge in demand made the problem worse. Giant companies like Ford are having to cut back on production – they recently cancelled shifts in two factories and reported the shortage would decrease their yearly profits by $2.5 billion.

Demand is growing faster than capacity

Chris Pearson, finance chief and business operations president of Newell, told the Wall Street Journal, “We do expect it to be a difficult supply operating environment for the rest of the year.”

Even in the slower first and second quarter, capacity has been strained to its limit. As spending picks up, the shipping industry is anticipating what might be one of the busiest holiday seasons in memory.

The good news for shippers is that rates are going up. As demand increases, customers will be willing to pay more for services. The conflict shippers will face will be using reduced assets to meet increased customer demand. It will be a precarious time when shippers might have to choose which customers they want to keep – and which customers they might not have the resources to serve.

How to make the most of limited capacity

While shipping companies won’t be able to do much about the underlying causes of the capacity crunch, there are strategies that will help them wring every minute out of the assets they do have:

1. Increase the time assets are used

Fleets are complex operations with assets spread across multiple loading docks, warehouses, and lots. It’s incredibly common for managers to simply forget about an asset for a short while. When that happens, businesses lose out on business they could have had. That’s why a tool like FleetUp’s utilization feature is so helpful – with the click of a button, managers can locate the asset that’s nearest to the job.

2. Decrease the time assets are at the mechanic

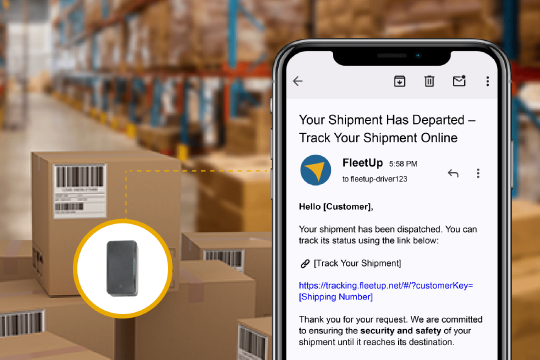

If assets are being used more often, they’re going to be in danger of breaking down sooner. During the busy holiday season, it’s not always possible to give every vehicle the regular inspections they need. Instead, use FleetUp’s eMaintenance tool. It monitors the status of engines in real time. The moment an engine is experiencing problems, an automated message is sent to the appropriate party via SMS or email.

3. Manage detention time

While ports, warehouses, and loading docks are going to be incredibly busy, there are always some operations that are managed more poorly than others. FleetUp’s detention time monitor automatically tracks how long vehicles are at places where they’re likely to be detained, so managers can identify the locations that are delaying traffic for an inordinate and unacceptable amount of time.

Increase your fleet’s capacity.

|